Demand rising for military simulation & training tech, virtual reality tools, and head-worn displays

StoryJuly 28, 2016

Cuts to the U.S. Department of Defense (DoD) budget over the last few years have created more demand for innovative simulation and training systems for military personnel, systems ranging from flight crews to radar technicians to maintenance teams across all services. In this Q&A with LeAnn Ridgeway, Vice President and General Manager of Simulation and Training Solutions for Rockwell Collins, she covers this trend and shares her outlook for the market long term, how the industry and the government is leveraging open architectures for simulation and training, and details new innovations such as virtual reality systems that enable the military to not only train how they fight by where they fight. Edited excerpts follow.

MCHALE REPORT: Please provide a brief description of your responsibility within Rockwell Collins and your group’s role within the company.

RIDGEWAY: We provide a unique function within Rockwell Collins as we are one of the few business units that serves the company’s commercial and government systems businesses. My role is Vice President and General Manager for the Rockwell Collins Simulation and Training Solutions business, headquartered in Sterling, Virginia. We provide the full spectrum of simulation and training for military and commercial customers. The solutions consist of visual products to complete training systems for aircrew and maintenance training.

MCHALE REPORT: Most of this decade has been about DoD budget cuts, which often push toward more reliance on training, especially simulated training, as it is overall less expensive. Was that the case and do you see the investment from the DoD growing over the next five to ten years for simulation and training systems?

RIDGEWAY: We did a whole study on this where we enlisted the Government Business Council to help us survey top-level DoD folks on short-term and long-term procurement trends for military simulation and training. We wanted fact-based data to ensure we are spot on with our investment and planning. Leaders surveyed in the DoD – the Pentagon and the armed services – confirmed that the DoD’s investment in simulation and training technology will continue to grow. We’ve seen solid growth year over year and are forecasting mid to reasonable high single digit growth over the next few years. We are seeing the DoD put money where they’ve said they were going to for quite some time.

Like the U.S., other ministries of defense (MoDs) around the globe are laying out similar multi-year plans and all have stated goals and plans to reduce the amount of live training they are doing to save operating dollars and constrain resources. Either they don’t have enough assets to train against and have to go to a simulation and training scenario or have new platforms such as the F-35 program that can only use simulation and training scenarios to prove out the most advanced technical capabilities.

MCHALE REPORT: Budget cuts also are known to drive more commonality in systems so they can work across multiple platforms, much like the FACE standard enables for avionics applications. Is that happening in simulation & training systems as well?

RIDGEWAY: We have the same philosophy as our colleagues in avionics at Rockwell Collins and use an open architecture for our simulation and training systems, called CoreSim. It is an open standard COTS-based architecture that we developed about eight years ago as we saw open architectures as the future not just in simulation and training but manned avionics systems as well. Open architectures -- much like the avionics community when the FACE standard was first announced – are still more of an aspiration in the military simulation and training community. Everybody wants it and is talking about it, especially for large-scale virtual training scenarios.

The technology is here as is the plug and play capability to make it happen, but it won’t for a while yet as the different armed services are still a bit like silos when it comes to procedures and legacy equipment. There are three primary standards in the military simulation community – Distributed Interactive Simulations (DIS), High Level Architecture (HLA), and the Test and Training Enabling Architecture (TENA). Getting to one isn’t going to happen soon as there is too much current fielded equipment in play with too many current training scenarios based on them.

However, we have worked with Navy to demonstrate a common network or layer above the simulation to finally put to bed the fact people don’t have to get rid of current fielded tech because the Navy had multiple vendors plug and playing in this live virtual constructive (LVC) scenario. Every vendor could participate thanks to common APIs. The Air Force has also independently released a simulated common architecture standard that is factoring in cyber security needs. Right after that announcement the Navy announced it is doing the same thing. The Army has been successfully running a Synthetic Training Environment (STE) that enables modular, open source, and open system architectures.

MCHALE REPORT: What are your DoD customers looking for in avionics simulations systems? Sensors simulation? Radar?

RIDGEWAY: They are looking for cloud-based solutions in addition to better realism and looking to train the way they fight. They also want to have more LVC, like we just talked about and reuse current equipment. We’ve demonstrated a few with the services AND will do another demonstration on August 17 at our facility. They want to be able to fly and drive ground assets such as dismounted soldiers, trucks, or light aircraft with live pieces interacting, and then throw fictional red forces at the trainees creating what are almost wargaming scenarios. For such an operation, training systems and participants are integrated in from multiple locations with live forces and all these independent entities are leveraging the same database like a map of Afghanistan. This is what the DoD leadership wants and is driving toward – linking that many people together, keeping a database correlated with sensors, then have everything from the avionics to the sensors correlated and viewed out the window – and all in real time.

MCHALE REPORT: Please provide an example or two of current simulation and training programs Rockwell Collins is involved with.

RIDGEWAY: A cornerstone program for us is providing simulation and training for the E2D Advanced Hawkeye’s aircrew and maintainer sides. We’ve been supporting this program for a few years and were recently selected as sole source for the Hawkeye Integrated Training System (HITS) 3 award. We have paired up with the prime on the aircraft, Northrop Grumman, to provide a comprehensive training system from classroom to computer from the back end systems to the front-end crewmembers as well as the maintainers. We provide the back end trainers for tactics, sensor analysis, etc. as well as the flight trainer curriculum courseware, electronic mission debrief, etc. (See figure.)

Figure 1:

(Click graphic to zoom)

We are just now implementing a system integration laboratory (SIL) for software development with Northrop Grumman and taking a live virtual demo from the SIL to the trainers for a LVC training event with the Navy. This work is also proliferating internationally as we recently won the contract to provide the simulation and training systems for France’s E2D upgrade.

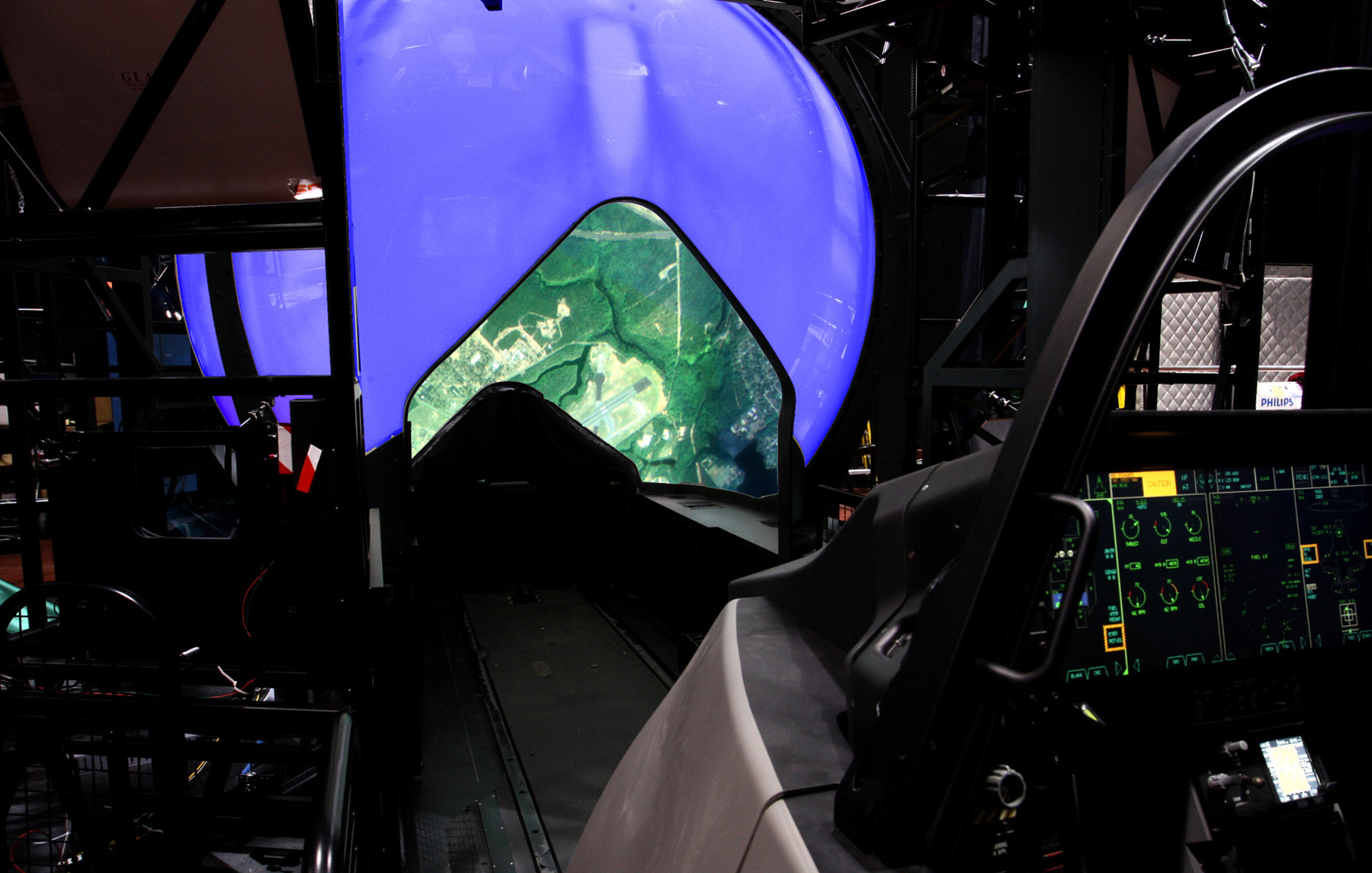

Another important program for us is the F-35 Joint Strike Fighter, where we are a subcontractor providing the F-35 pilot’s visual system to Lockheed Martin. It centers around the helmet worn display, but comprises 360 degree field of view dome solutions and image generators, projectors as well as databases. F-35 pilots are now integrating the new Gen III helmets with a new level of complexity into simulation training scenarios and this is the same helmet they will use in the aircraft.

MCHALE REPORT: Much realism in today’s military simulation is said to have come from the commercial gaming community. Do you still leverage commercial technology commercial-off-the-shelf (COTS) equipment or is there still a significant amount of custom in military simulation systems?

RIDGEWAY: There is a limitation on what games can do. They are very good in applications such as first-person shooter or dismounted soldiers, and other applications that really don’t need moving models, large areas, and complex sensors. If you play a first-person shooter game and you may see really detailed scenarios with great clarity especially with geographically small locations. But in advanced flight scenarios you need high-level computational and texture memory performance and COTS-based gaming components and commercial graphics cards cannot handle that performance requirement. Our image generators use as much COTS as possible, but often when we are looking at graphic cards and FPGAs for these complex scenarios we do custom designs to meet the training requirement and real-time computation. They require flying a jet though extreme weather and full battle conditions, which is a leap that cannot be made by commercial gaming technology at this time.

We are taking the best of both worlds, however, and are partnered with the University of Utah, one of the top gaming universities in the country and working with students and professors to leverage the innovation they doing in the gaming world and leveraging it for complex defense and aerospace simulation systems.

MCHALE REPORT: How do you manage obsolescence when leveraging COTS? Any lessons learned you can share?

RIDGEWAY: We use multiple layers of obsolescence prediction. The nice thing about moving into the simulation and training business from a previous role at Rockwell Collins, which focused on obsolescence management, is that we easily brought that process to simulation and training. We work with the component applications engineer and use our system for tracking obsolete parts, as one would expect, but using our own FPGAs also gives us control over the component’s lifecycle, which we wouldn’t get from a commercial chip, where would be held hostage to the PC and gaming world. In other areas where we use standard COTS graphics cards and motherboards we work with manufacturers to create a technology baseline and coincide it with new development. This allows us to change out components every 18 - 24 months if need be and work as best as we can to be backward compatible. Customers will not have to change out all their top-level equipment, such as getting a new image generator. We use this process to sustain products in the field for as long as 15-20 years.

MCHALE REPORT: How are reduced size, weight, and power (SWaP) requirements impacting simulation designs? Have advances in SWaP enabled more portable training solutions for instance?

RIDGEWAY: It has for sure. SWaP is important for reducing the cost and being able to provide persistent training and we continue to see an appetite for smaller, lighter, faster technology. There is a huge emphasis on extending battery life and reducing the heat generated in modern computing systems. There are great products in avionics and man wearable applications that we would like to be able to port into the simulation and training arena. For example the U.S. Navy is bringing training systems onto aircraft carriers for not only navigation and sensors, but for every area of the ship even maintenance of the engine room. These simulators are no longer huge, basketball-court sized displays, but often handheld or head-worn systems.

Modern transportable simulators are even more powerful than laptop computers with everything moving toward head-worn applications and virtual reality training. Technology today takes that 11-foot display wall down to a close-to-your-eye visual in head-worn system. These trends are revolutionizing simulated training. Wearable type solutions allow the trainee to essentially train anywhere. The reduction in hardware from reduced SWaP requirements fuels the development of portable training and also indirectly cloud-based training.

MCHALE REPORT: Many recruiters in the defense industry find it hard to attract engineering talent away from the commercial tech giants such as Google and Facebook. Is that the case for simulation and training as well or does its similarity to the commercial gaming world negate that trend?

RIDGEWAY: We have not had any problem. It surprised us when all of our engineering interns chose – once they finished their internship – to come work with us. Many were attracted because as opposed to the commercial gaming industry, what we develop for the military and aerospace world is real stuff and real life. We’ve been blessed to have just about 100 percent of our college interns graduate and come to work with us. It even surprised me. I imagine it does help that many are working in our Salt Lake City image generation database facility, which is right across the street from their school, the University of Utah.

MCHALE REPORT: Looking forward, what disruptive technology/innovation will be a game changer in the simulation and training world? Predict the future.

RIDGEWAY: The single biggest thing in the near-term is going to be head-worn applications. When you think about the advances in near-eye display technology such as Oculus from Facebook, they’re revolutionary for human interactive training and at the same time provide unparalleled situational awareness to the warfighter. When you look at the combination of near-eye displays and the expansion of cloud-base streaming pipeline you see a door opening to mixed virtual reality training.

The technology is here, but it still has challenges such as inefficient resolutions, narrow fields of view, and limited bandwidth. All of this will need to improve before it can be leveraged in real-time military training simulation environments. The industry is moving to solve these challenges and will, but I have a one caution. While this blend of technology will be huge with what it enables us to do with adaptive and distributed training, we will see so much technology coming out so fast and changing so rapidly that knowing what to adopt and where to put funding will be very confusing. It could also be detrimental to mission effectiveness if the new technology is not tested as to training outcomes first.

Another big trend I see starting is more scientifically-based biometrics around equipment training that will enable head-mounted systems with the same level of efficiency as end users get from traditional live or simulated training. We are spending a lot of time and research at Rockwell Collins on these developments to make sure we put our funding where the training objectives will be and with the latest technology hitting the market. The commercial world pours billions into developing technology such as Oculus and making sure people don’t get simulation sickness and overcoming other human factor challenges, while in the military simulation and training world we write the applications that adapt that low-cost technology for mission-critical training.

As Vice President and General Manager of Simulation and Training Solutions for Rockwell Collins LeAnn Ridgeway is responsible for the company’s simulation and training business that includes technical publications, re-hosted avionics, computer and desktop training, training devices, and visual systems. Previously, she was Vice President and Managing Director, Americas for Rockwell Collins and before that served as senior director, Engineering Services for Rockwell Collins, leading a global network of 400 company field service engineers providing complete life cycle service and support for installations, operations, maintenance, upgrades, and repairs. Additionally, she led the company’s Integrated Logistics Support Organization. A native of Anamosa, Iowa, LeAnn earned her bachelor’s degree in Business and Economics from Mt. Mercy College and her master of business administration degree from St. Ambrose University. She is currently a member of the National Training and Simulation Association, the National Defense Industrial Association, Women in Defense, Washington, D.C. Chapter, and is the Enterprise Chair for the Women’s Forum at Rockwell Collins.