Predictive maintenance potential outlined in 3-D printing study

NewsMay 22, 2020

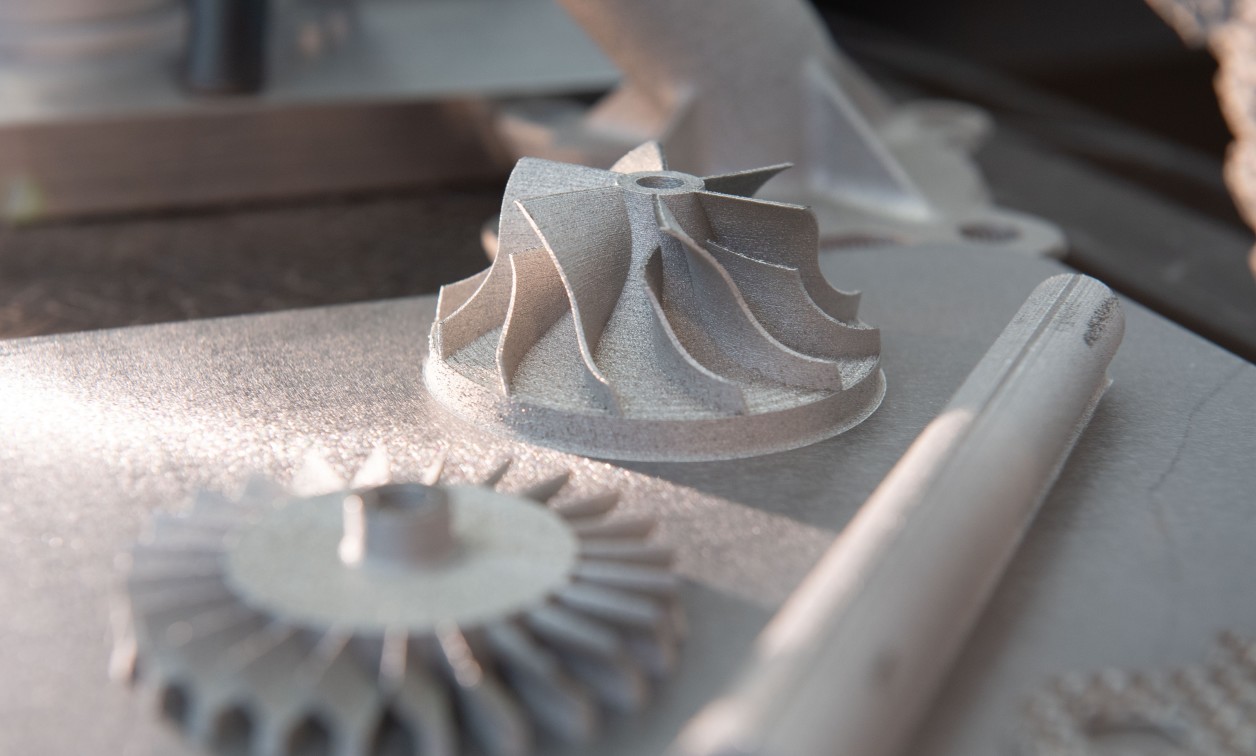

ABERDEEN PROVING GROUND, Md. A new study published in the International Journal of Advanced Manufacturing Technology showed that the U.S. Army could detect and monitor the wear and tear of 3-D printed maraging steel through sensor measurement.

This study was led by a team of researchers from the laboratory, the National Institute of Standards and Technology, CCDC Aviation and Missile Center and Johns Hopkins University, who likened cues from the material’s performance to a vehicle odometer reading that signals a need for an oil change.

Officials want to develop a tool for measuring the unique performance of each 3-D printed part acknowledging that each is different via sensor measurement. Researchers claim the imperfections in 3-D printed parts are typically attributed to voids and geometric variance between the computer model and the print. Sensor technology in development offers a way to track individual parts, predict failure points, and replace them a few cycles before they break.

Army researchers are applying these findings to new studies on 3-D-printing of stainless-steel parts and using machine-learning techniques, instead of sensors, to characterize the life of parts, according to officials.